Navigating Challenges in Tempering Channel Glass: A Closer Look at the Complex Process

2024-05-11

To meet strength requirements, certain designs necessitate the utilization of tempered Channel Glass. However, the tempering process for Channel Glass diverges from standard flat glass, rendering manufacturers capable of Channel Glass tempering quite scarce. Let's delve into the challenges from five distinct perspectives:

1. Stringent Standards:

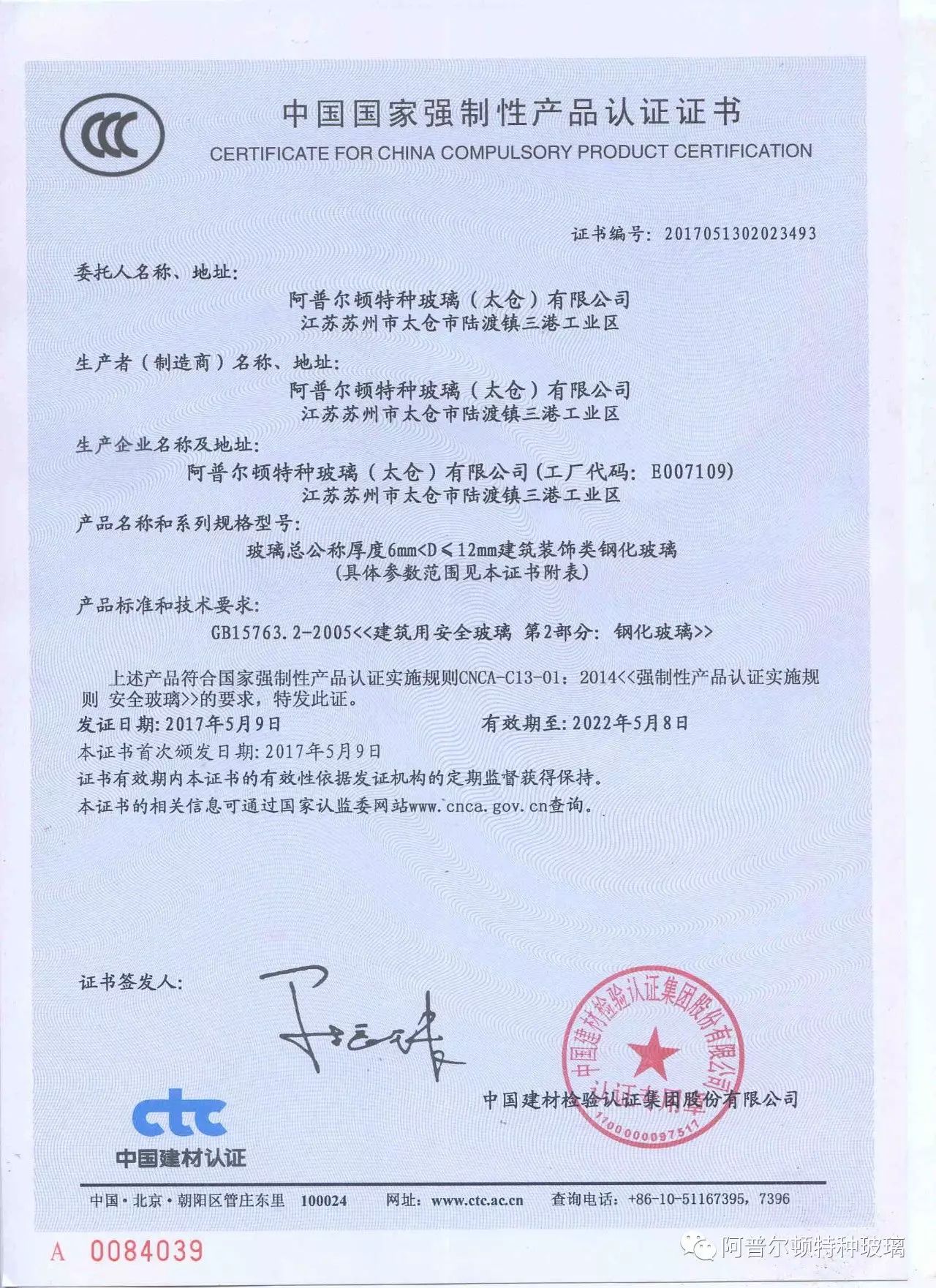

Currently, specific standards for tempered Channel Glass are lacking in China. For CCC certification, Channel Glass must adhere to the national standard "Safety Glass for Building: Tempered Glass." Adapting the comprehensive set of tests designed for flat glass, including challenges in fixing methods, compliant fixtures, and specialized gauge calibration, poses significant hurdles for Channel Glass.

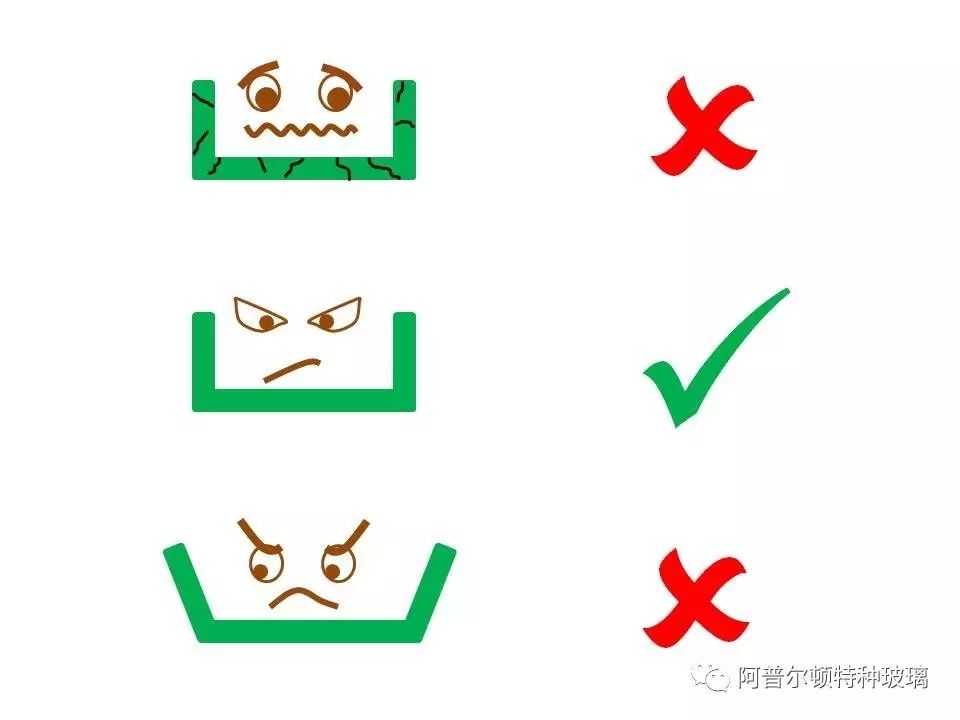

2. Balancing Act:

The primary challenge in the tempering process for Channel Glass is concurrently meeting safety and dimensional requirements. Safety requirements manifest in three key tests: impact resistance, fragment status, and hail bag impact performance. Impact resistance testing, particularly stringent, demands a 1040g steel ball dropped from a height of 1000mm to hit the glass without causing damage. To achieve the required strength, the glass must undergo sufficient heating and rapid cooling. However, excessive heating softens and distorts the glass, while excessive cooling causes flange distortion. Only by achieving balance across all aspects of the process can high-quality tempered Channel Glass be produced.

3. Equipment Capability:

Globally, tempering furnaces specifically designed for Channel Glass are exceedingly rare. Most Channel Glass tempering on the market relies on small tempering furnaces, making it challenging to produce qualified Channel Glass due to stability and equipment capacity issues. Appleton's tempering furnace for extra-large Channel Glass surpasses the requirements of the Channel Glass process in terms of heating and cooling capacity. Additionally, the production line's high level of automation rigorously controls each key process parameter and continuously monitors subtle process changes to ensure the stable quality of the finished product.

4. Production Experience:

Exercising control over the production of original Channel Glass and possessing ample experience in tempered flat glass are indispensable prerequisites for tempering Channel Glass. Currently, few manufacturers possess both Channel Glass production and tempering capabilities. Since 2008, Appleton has been producing rolled glass and tempered glass, fully mastering the entire process from raw material ratio, rolling forming, annealing, edging, to the full tempering process. With mature theoretical support and continuous training and support from Pilkington, Appleton has accumulated valuable experience and cultivated outstanding talents during nine years of continuous production.

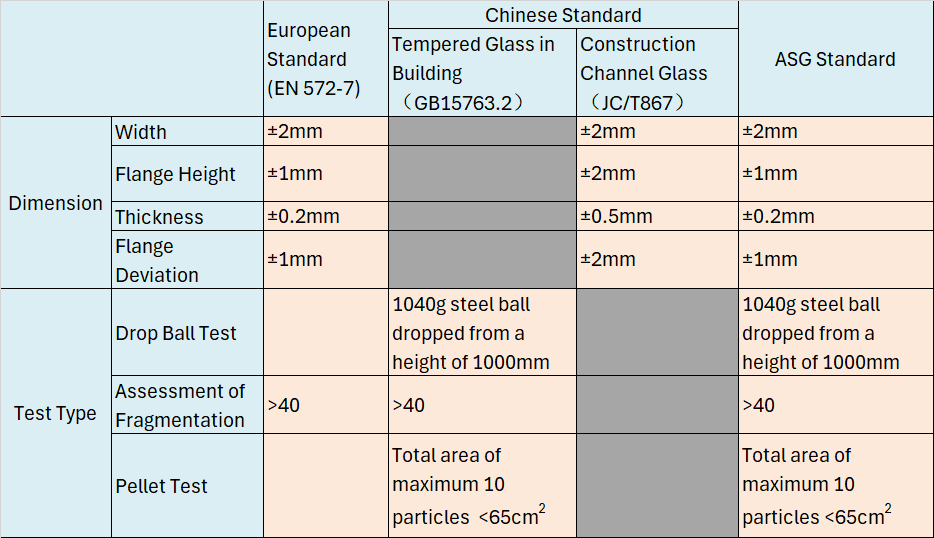

5. High Standards — ASG Standard:

Due to differences in European, national, and industry standards, most products on the market can only meet one or two standards simultaneously. To manufacture the finest products, ASG's Channel Glass adheres to strict internal control standards, ensuring that the final product can simultaneously meet domestic and Channel Glass-related standards.

The secret behind Appleton's successful one-time CCC certification lies in the fusion of theory and practice, coupled with the use of sophisticated equipment.